OUR ADVANTAGE

Murakami’s Strengths

Murakami is a manufacturer of photo emulsions and capillary films for screen printing, and since our founding, we have worked hard to develop unique photo emulsions and capillary films—with capabilities that are world class in terms of performance and production volume. The originality of Murakami is based on a combination of two technologies: screen stencil technology that enables printing in micrometer units, and photo emulsion and capillary film technology to support screen stencils. Murakami expanded overseas at an early stage, so our photo emulsions and capillary films are used in more than 50 countries, customers all over the world.

Photo Emulsion and Capillary Film

Development of cationic polymerization based photosensitive materials that develop in neutral water

We were the first in the screen printing industry to commercialize cationic polymerization based photosensitive materials that develop in neutral water.

In this way, we have also supported the manufacturing sites of our customers from an environmental perspective through products with the outstanding environmentally-friendly characteristic of water development.

Other products we’ve put special effort into developing in recent years include rotary emulsions that do not use bichromate, and non-VOC photo emulsions with a water medium and that develop in neutral water.

Development of PVA-SBQ photo emulsion and capillary films

In 1985, we were awarded the 10th Inoue Harushige Prize for successful “development and commercialization of PVA-SBQ photosensitive resin (photo emulsions and capillary films for high-precision screen printing).”

At that time, the mainstream photo emulsions for screen printing were bichromate, diazo resin and the like, but these photo emulsions have a short pot life and are sold in two-component form. They were troublesome because the customer had to mix them at their printing site. Taking note of the long pot life of PVA-SBQ photo emulsion developed at the Agency of Industrial Science and Technology (currently known as the National Institute of Advanced Industrial Science and Technology), Murakami successfully commercialized a one-component photo emulsion by exploiting the features of such materials, and thereby helped shorten our customers’ manufacturing processes.These materials have outstanding performance such as dramatically reducing exposure time compared to bichromate and diazo resin, and for these and other reasons have been highly acclaimed by the screen printing industry all over the world as revolutionary photo emulsions.

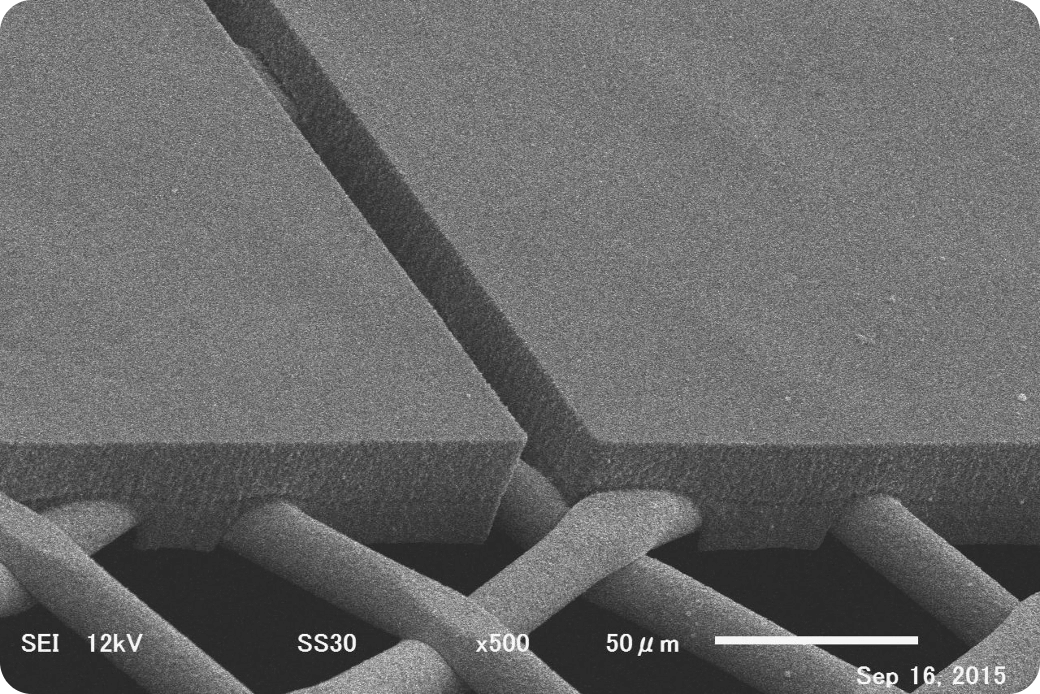

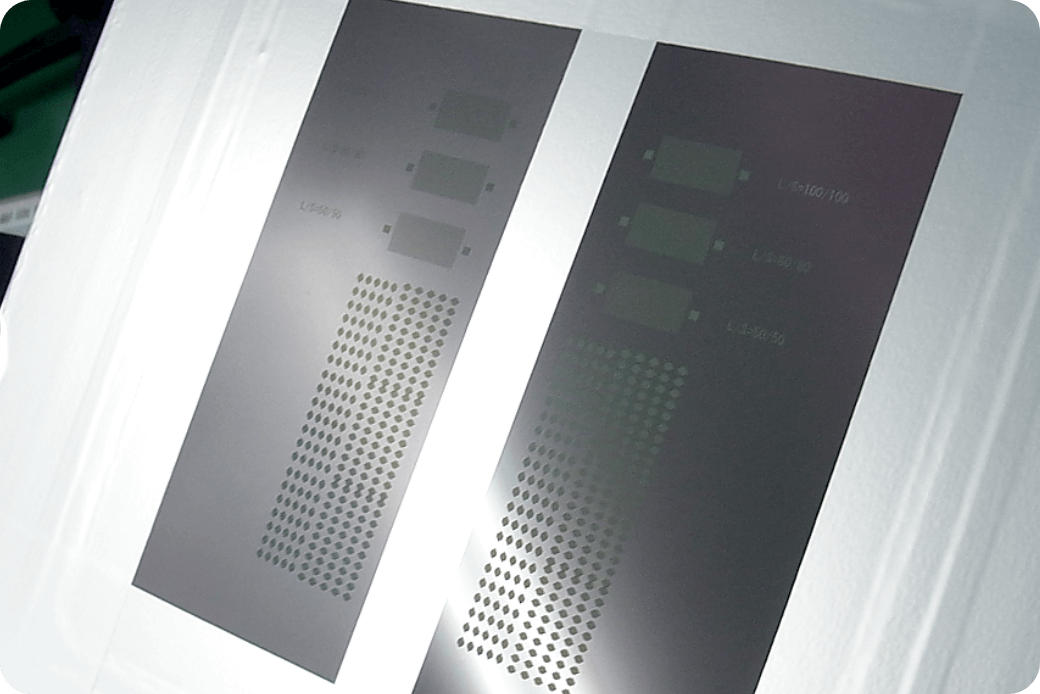

Capillary film

We have established a specialized coating technology for water-based resins, which is one feature of our photo emulsions and capillary films for screen printing. The technology has a coating history of 40 years. Coating is done in a Class 1000 cleanroom, and efforts are being made to develop products responsive to film thickness/thinness tolerances. The sophistication of our technical capabilities is regarded as world-class and Murakami capillary films are used all over the world.

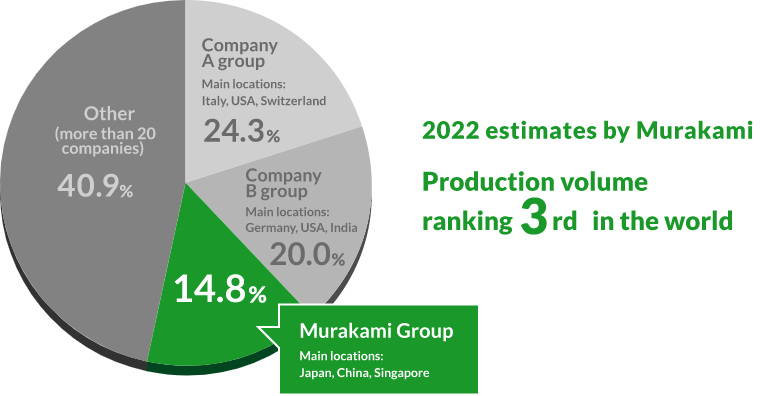

No. 3 in the world in production volume

In 2019, worldwide production of photo emulsions and capillary films for screen printing was estimated to be approximately 12,000 tons. Murakami’s share of this production ranks third in the world at just under 15%. The main reason why Murakami photo emulsions and capillary films—whose forte is precision screen stencils—rank third in production volume is because the screen stencils used by electronic application customers opposed to other applications are comparatively small, reducing the amount of photo emulsion and capilary film being used.

Percentage of global photo emulsion and capillary film production

Screen Stencils

Murakami screen stencils feature thinning in micrometer units and technology with high positional accuracy. They are used primarily for applications like electronic components, solar panel electrodes, and touch panels, and they support the world’s cutting-edge technologies.

Wide array of options

We support high-quality printing by proposing screen stencil options meticulously adapted to the each customer’s printing environment and needs. Examples of products using our technology include graphics, PCBs, automotive onboard parts, and electronic components.

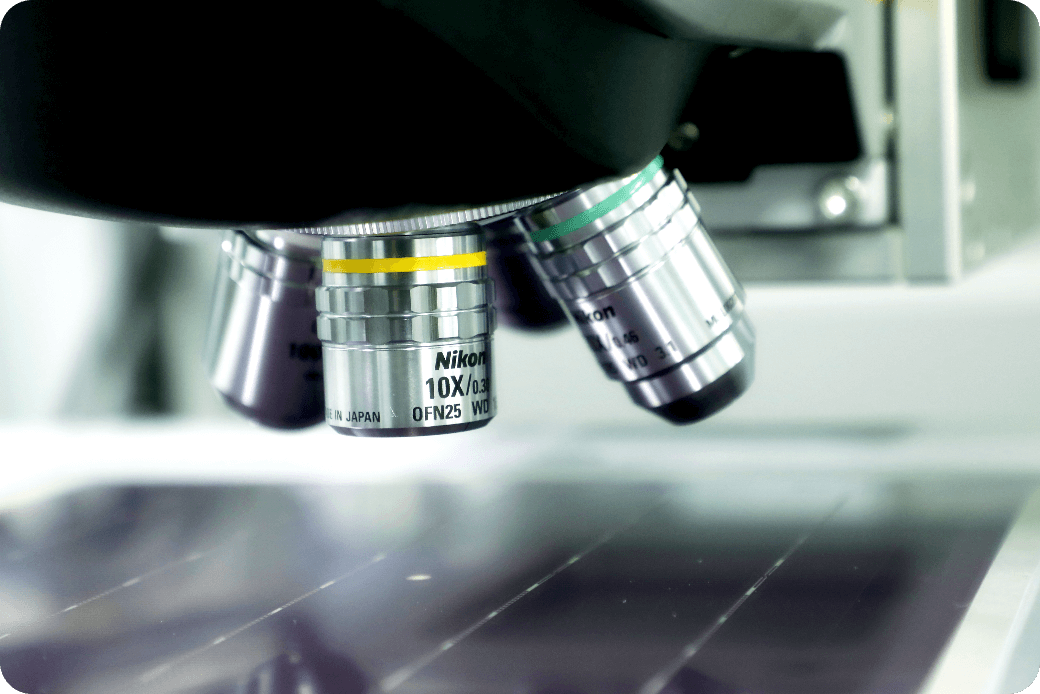

Test equipment supporting high quality

We provide optimal screen stencils to meet customer needs through repeated screen stencil and printing tests of all kinds.

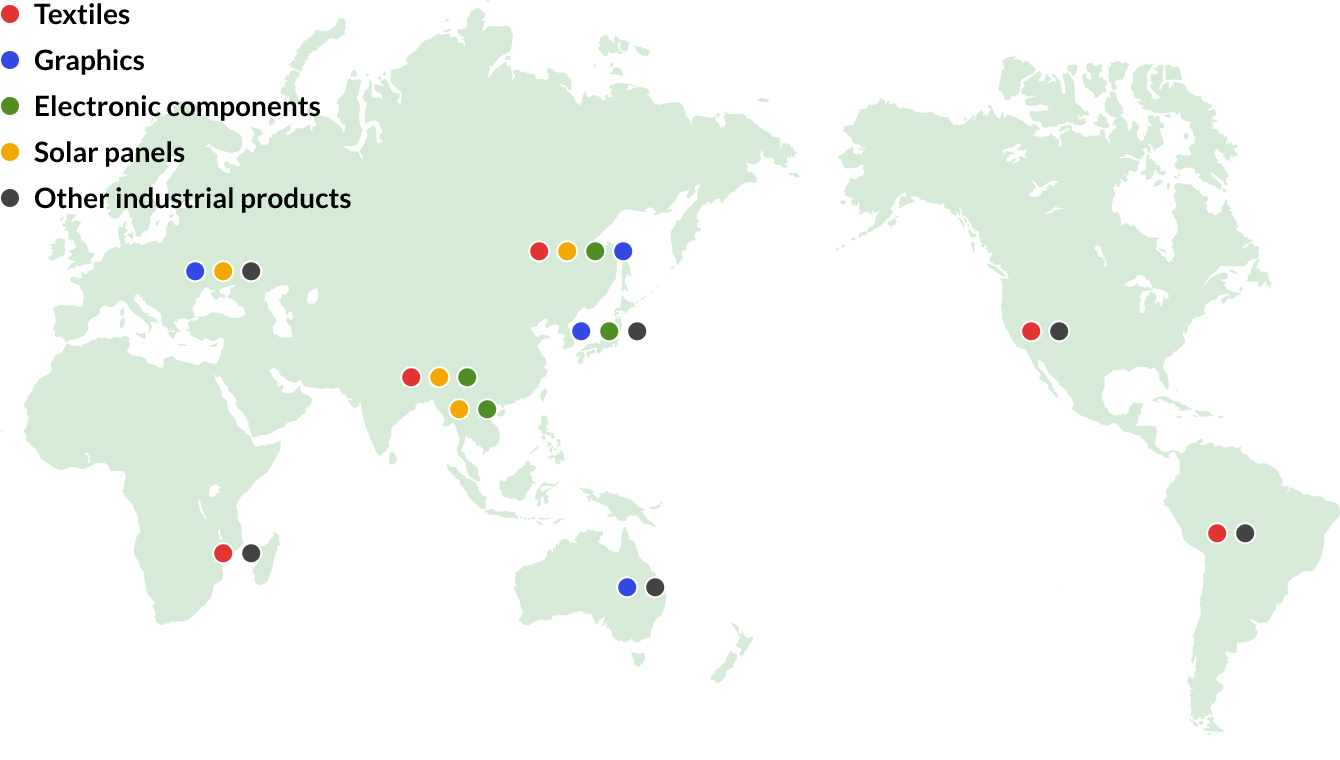

Global Expansion

Screen printing used all over the world

Today, Murakami photo emulsions and capillary films boast an outstanding reputation in the screen printing markets of more than 50 countries worldwide, and they are used in manufacturing an extensive array of products ranging from graphics, to PCBs and finely-patterned electronic components. We also manufacture photo emulsions and capillary films in Japan, Singapore, and China, thereby improving convenience for customers and hedging risks.

Network

We have wholly-owned subsidiaries in the USA, Singapore, China, and South Korea, and we provide Murakami photo emulsions and capillary films, screen stencils, and screen printing materials/equipment worldwide, including exports from Japan.