R&D SYSTEM

Murakami’s R&D System

We are engaged in a broad range of R&D—from development of photosensitive resins, to research for improving functionality of screen stencils, and print testing. Every day, we are working to expand the possibilities of screen printing.

R&D System:

Introducing Our R&D Center and Interviews

Here we introduce Murakami’s R&D efforts through interviews with young employees.

R&D System

We are engaged in a broad range of R&D—from development of photosensitive resins, to research for improving the precision of screen stencils, and print testing. Our research system handles development of all products sold by Murakami, and is working every day to expand the possibilities of screen printing.

Research and Development Department

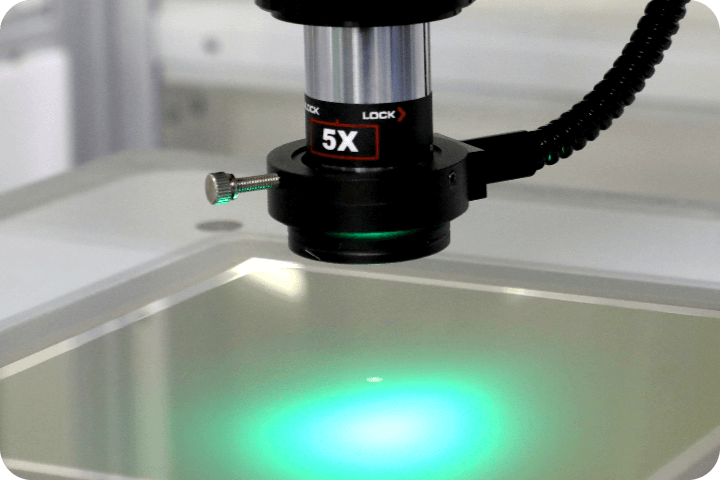

The mission of the R&D Center is to develop and commercialize photo emulsions and capillary films that enable optimal printing results to be obtained in various fields.

Applications of screen printing are diverse, ranging from textile printing to printing electric and electronic components. Screen stencil materials are made up of frames, screen meshes, and photo emulsion and capillary films, and it is no exaggeration to say that what determines the reproducibility of printing is the performance of photo emulsion and capillary films. The mission of the R&D Center is to develop and commercialize photo emulsions and capillary films that enable optimal printing results to be obtained in various fields.

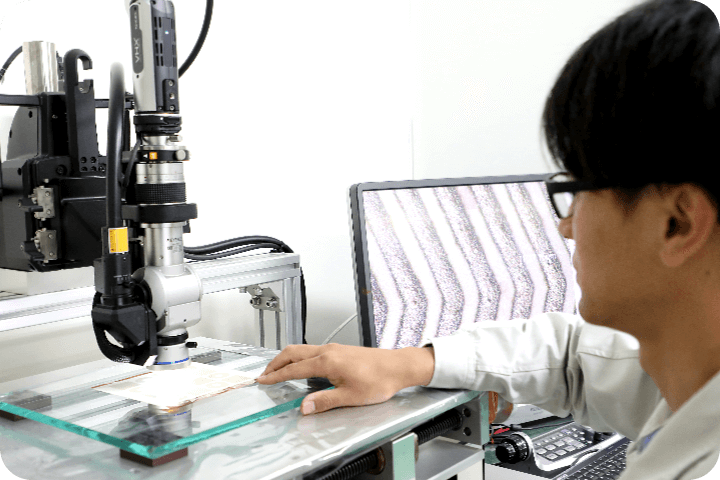

Engineering Department (Engineering Section, Quality Engineering Section)

To support stabilization of production and quality of screen stencils

In functional printing of electronic components and electric/electronic devices, such as MLCCs and inductors, there is an increasing need to provide not only thinner lines and higher precision than ever before, but also stable quality. Our Engineering Department supports Murakami manufacturing from two directions: manufacturing technology for enhancing screen stencil functionality and improving processes, and quality technology which strives for stable quality.

Murakami Techno (R&D base)

In April 2013, we unified our domestic Engineering Department and established the R&D Center at Chiba Office No. 2. After that, in March 2020, we transferred all R&D operations to MURAKAMI TECHNO CO., LTD., and established a system enabling efficient technology development with greater specialization.

MURAKAMI TECHNO, Company profile

| Company name | MURAKAMI TECHNO CO., LTD. |

|---|---|

| Head office address | 〒267-0056 At Chiba Office No. 2 in Chiba Toke Midori-No-Mori Industrial Park located at 1-6-12 Onodai, Midori-ku, Chiba-shi, Chiba |

| Established | March 1989 |

| No. of employees | 24 (as of Feb. 29, 2024) |

| Capitalization | ¥12 million |

| Nature of business |

|

| End of fiscal year | February |