FAQ

- Top page

- FAQ

Photo Emulsion and Capillary FilmEmulsions/Capillary films/Other

-

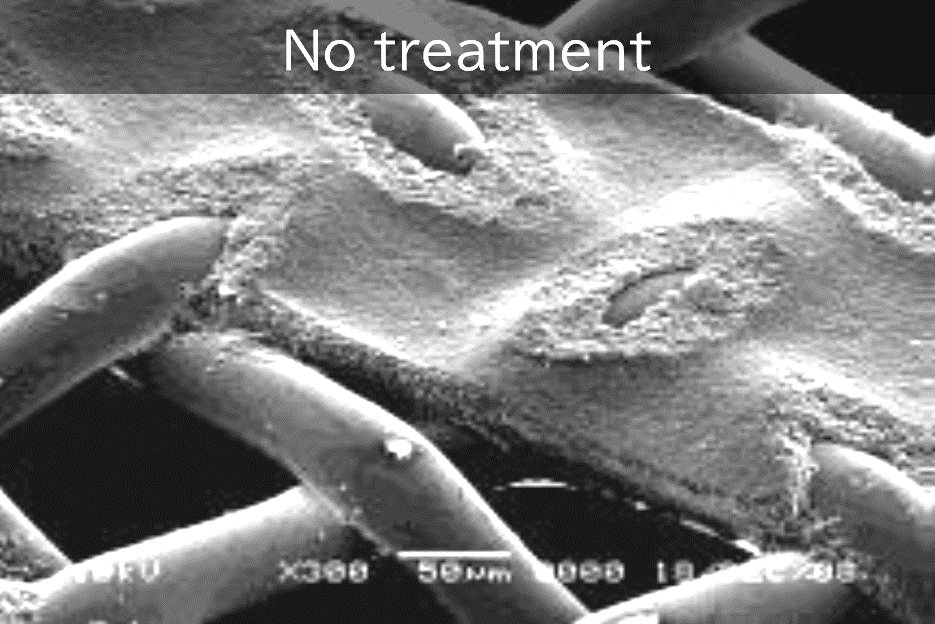

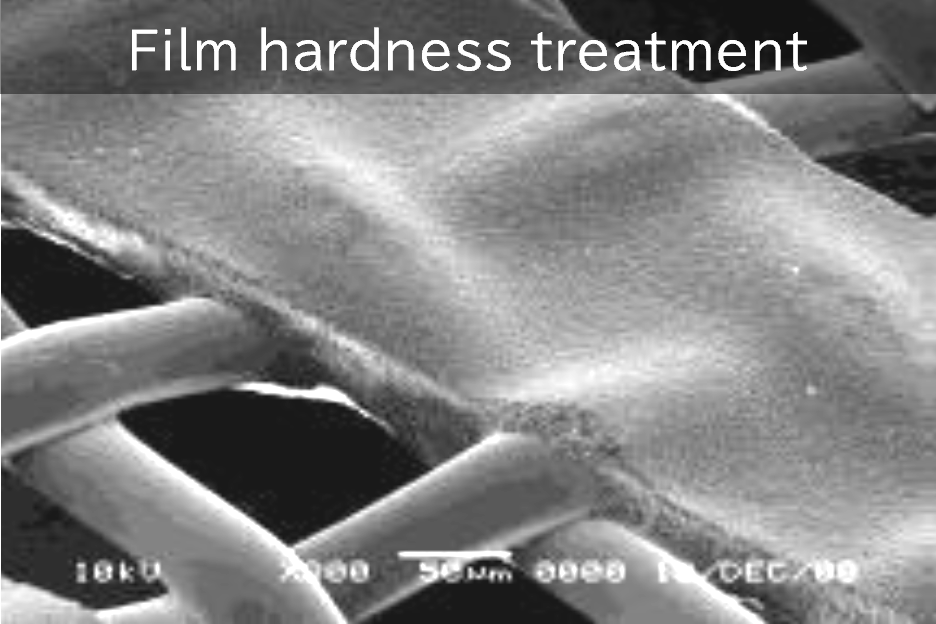

What is “film hardening treatment”?

A “film-hardening agent” is a chemical agent that improves an emulsion’s water resistance performance.

Based on how the name sounds, one might believe that it is an agent that spreads a film which strengthens the surface hardness of a photo emulsion and capillary film, but film hardening in the context of screen printing refers to a substance that improves water resistance (or solvent resistance).

A photo emulsion and capillary film is a light-curable, photosensitive resin developed with water.

Due to its characteristics, it has a property of low water resistance, wherein it absorbs water (swells) even after being cured with light.In printing, it swells with the solvent components contained in the ink paste; it also absorbs solvents and water and swells in washing after printing.

In its swollen state, it becomes abraded when force is applied by, e.g., using a squeegee or wiping the stencil during washing, whereby it wears away.

The film-hardening agent inhibits swelling due to coating the photo emulsion and capillary film with a chemical agent, enabling an improvement in durability.

A one-component type and a two-component type are available, but due to the two-component type being more effective, we generally recommend the two-component type.

-

Where can SDS (safety data sheets) for photo emulsion and capillary films be obtained?

We can provide a photo emulsion and capillary film SDS (safety data sheet) for each type, but this cannot be downloaded from the homepage.

Please make a request after filling in the necessary fields in an inquiry form, etc. We will send the data separately.

Screen StencilsPlate Specifications/Options

-

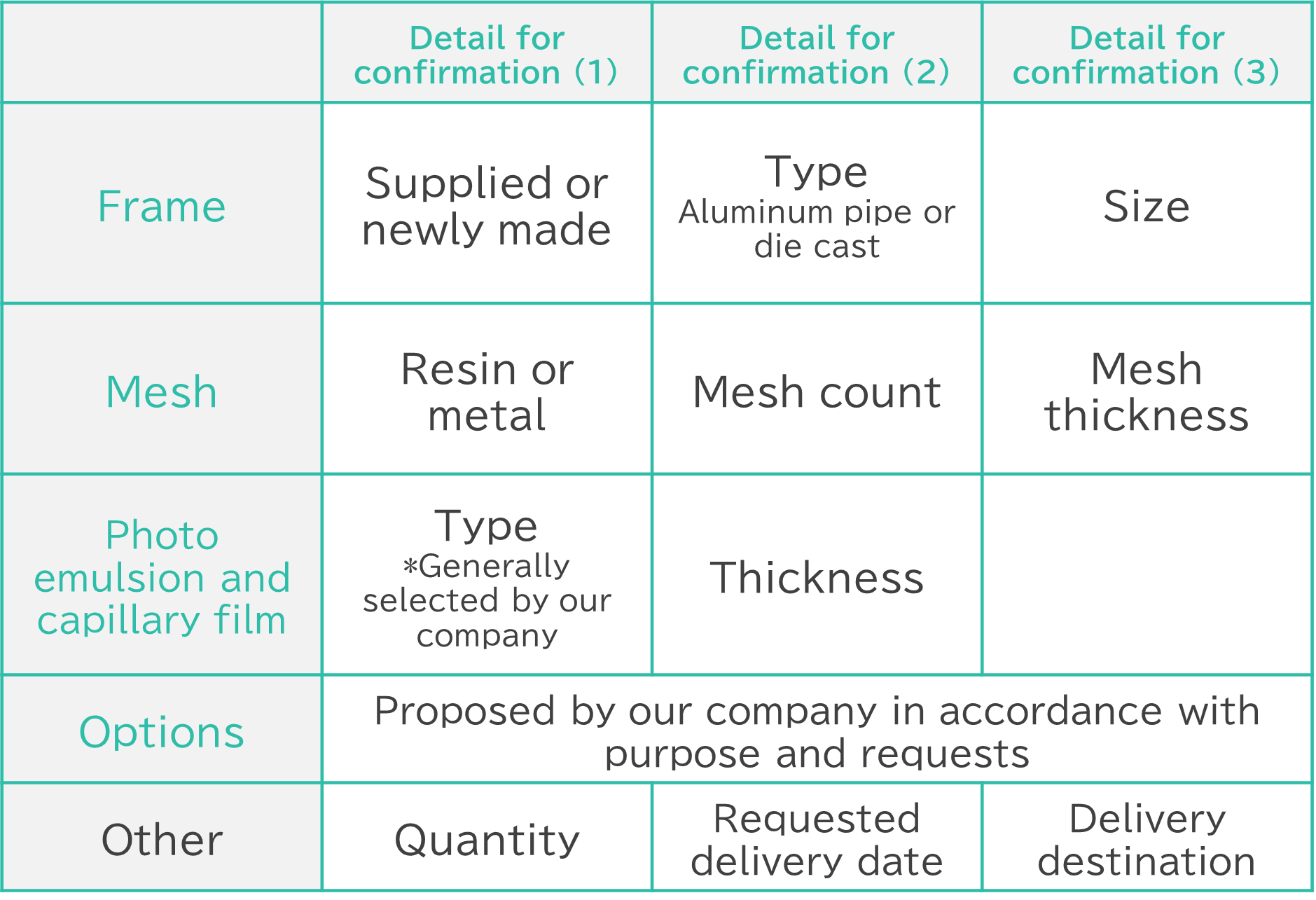

What is the “necessary information” when ordering screen stencils?

In order to optimize screen stencils, we conduct preliminary meetings with customers when undertaking screen stencil production.

Even in cases of repeat orders or the customer having decided the specifications, we have the customer provide the four following necessary pieces of information.The four main elements are “frame,” “mesh,” “photo emulsion and capillary film,” and “options.”

-

I want to outsource a part of the screen stencil production process. Is this possible?

Yes, it is possible.

Screen stencil production is broadly divided into three processes.

- Stretched screen: A state in which a screen mesh is stretched over a frame

- PS stencil: A state in which a photo emulsion and capillary film is applied on the stretched screen(before exposure)

- Screen stencil: A state in which the pattern is exposed and developed

Products are made and sold for each of these three processes.

A sales representative can provide the details, so feel free to inquire.

Inquiry Form -

Which screen stencil options should I select?

We propose recommended specifications in accordance with the printing details and purpose.

For screen printing, it is important to optimize three major conditions.

- Paste conditions (characteristics, elasticity, viscosity, etc.)

- Screen stencil conditions (mesh, emulsion, tension, options, etc.)

- Printing conditions (various parameters on printer side, etc.)

Generally, we have customers provide information regarding (1) paste conditions and (3) printing conditions.

Based on the information we have been provided and our experience, achievements, and research data to this point, we propose the screen stencil optimal for the customer. -

Are there rules, etc. for the methods for handling screen stencils (storing conditions and cleaning methods)?

In order to maintain performance and extend life, handle the screen stencil with care.

Storage of screen stencil before printing

(1) With regard to the storage location, please store in a location without direct sunlight that falls within a temperature range of 10 to 30°C.

- Direct sunlight causes the photo emulsion and capillary film to undergo an excessive reaction, leading to dimensional shrinkage.

- At extremely low temperatures, the photo emulsion and capillary film cracks (the photo emulsion and capillary film becomes unable to withstand expansion and contraction of the screen), and at high temperatures, there is permanent warping of the image due to expansion.

(2) Do not subject to strong impacts such as falls.

- Strong impacts may cause breakage, a decrease in tension, a decrease in positional precision due to warping, etc.

(3) Allow the stencil to adjust to the printing environment before printing (*at least 3 hours before).

- Allowing the stencil to adjust to the temperature/humidity inhibits changes over time.

Storage of screen stencil after printing ends(1) Clean the stencil such that no paste/ink remains on the openings or the stencil surface.

- Do not rub with excessive force.

(2) Store on a storage shelf, etc. after thoroughly drying the solvent, water, or other cleaning material.

- A swollen state continuing over a long period deteriorates the abrasion performance of the stencil.