What Is Screen Printing?

- Top page

- Product Information

- What Is Screen Printing?

-

*This is a technique in which ink or a coloring material is painted over a pattern paper having designs or characters cut out of it to transfer those designs; the “thread hanging” for holding the cut-out designs can be deemed to be the prototype of the appearance of stretched mesh. Screen printing is a type of mimeographic printing. Mimeographic printing is a printing technique in which holes are made in the plate itself, and ink is rubbed through from there.

Tracing back the history of this technique, it is said that the origins thereof are the methods/techniques of stencils and Japanese “yuzen dying (*kata yuzen and printing yuzen).”

Taking this as a hint, in 1907, the Englishman Samuel Simon received a patent for “silk screen stencils,” in which silk is used, and this came to be known as silk screen.

-

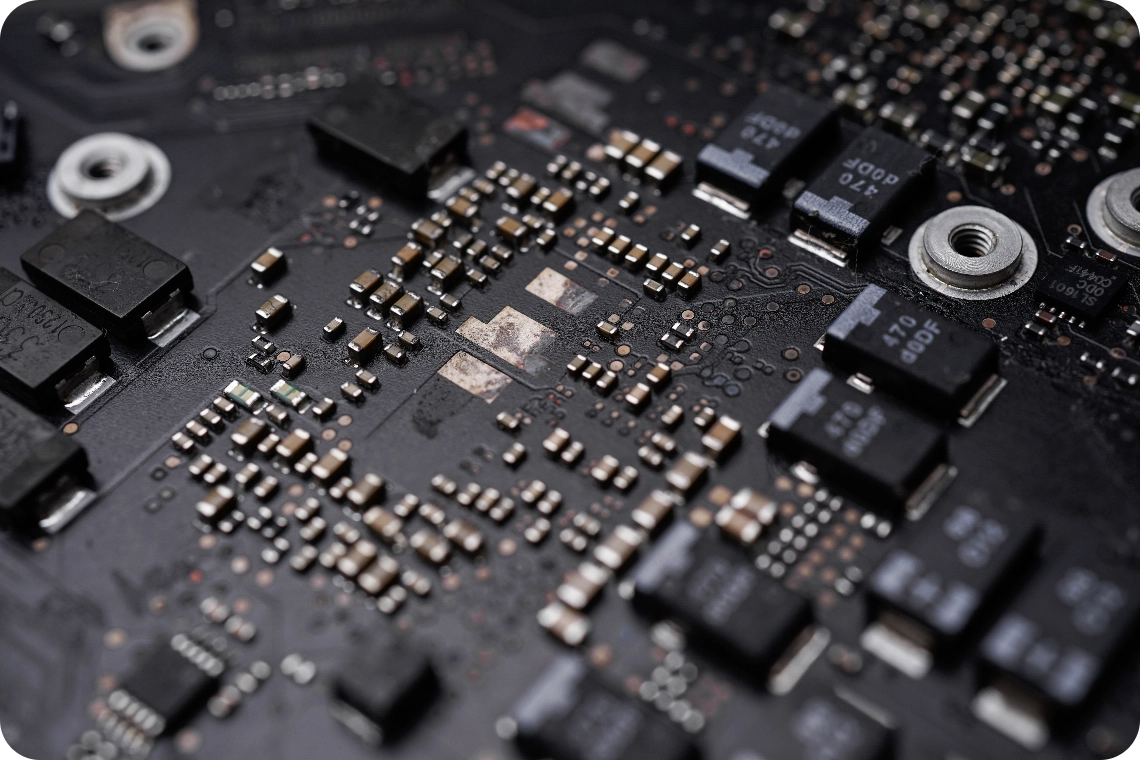

In screen printing, the design to be printed is formed on a screen mesh using a resin called an emulsion, and printing is carried out by pressing the ink using a squeegee. (Ink is transferred onto portions with no resin (open portions) to print the design.)

Currently, screen mesh does not use silk; there are many options of material in accordance with the usage purpose, which include resin substances such as polyester and nylon, and metals such as stainless steel and tungsten.

Further, a major characteristic is that due to flexibility via the mesh, the printing target can be various materials other than paper, regardless of the stiffness and irregularities of these materials. Examples of such materials include glass, plastics, metals, and fabrics.

-

Since screen printing does not limit the printing target, printing on base materials having some irregularities, etc. is enabled. Moreover, since it is only required that the ink to be used is in a paste form, the ink component(s) can be designed and selected relatively freely.

It can be said that this is a printing technique that responds to needs in electric/electronic component printing: for example, due to recent developments in technology, it has become possible to print fine wiring having a diameter of around a mere 10 µm (the diameter of one strand of human hair is 60 to 80 µm).

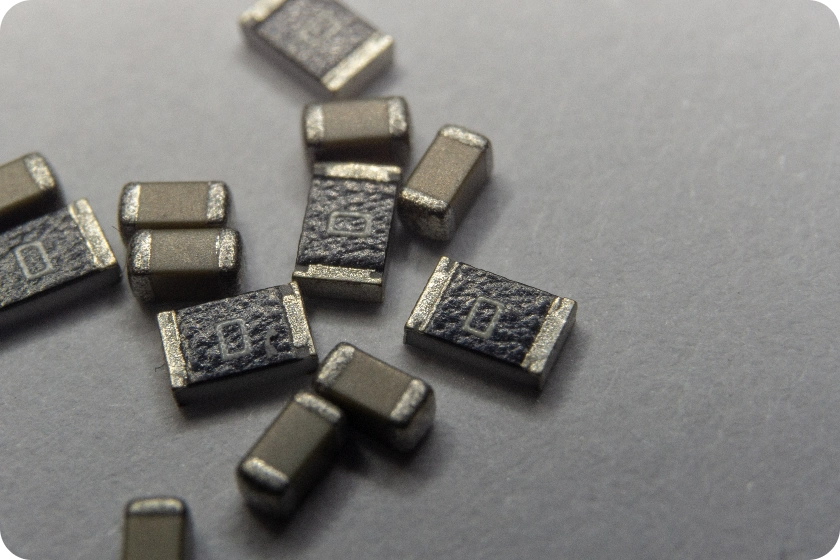

*Electrodes within fine chip components, as shown, are often formed by screen printing.